Kitchen

What is Dovetail Construction?

Dovetail joinery is a type of tongue-and-groove (or tail-and-pin) box joint. The tongue is a piece of the wood board that sticks out, and the groove is the space it fits into on the adjacent board. Tongue-and-groove joints are popular for making doors, flooring, and architectural paneling.

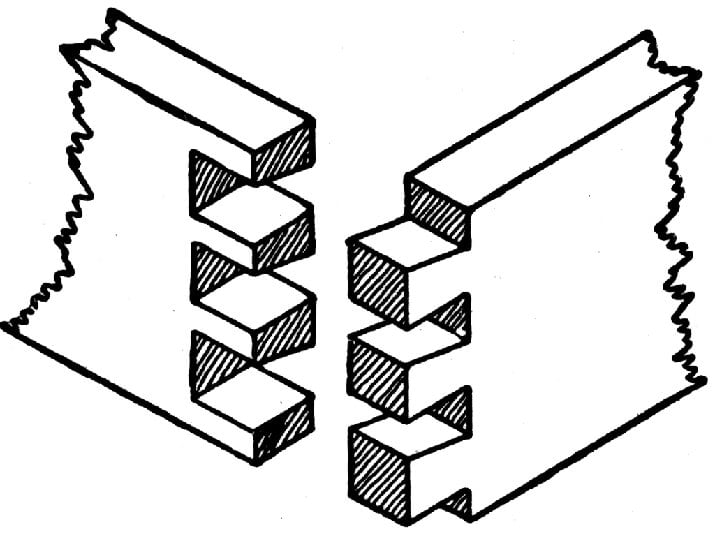

In dovetail drawer joints, the tongues look like actual dovetails, and the grooves are spaces cut to accept those pieces. Look at the image above. You can see that the widest part of the dovetail is deep into the other wood board. This makes pulling off the front of the drawer almost impossible.

No matter how hard you pull open the drawer, it should stay together. The hardware and drawer slides would probably break before the wood would come apart. A dovetail joint can stay together on its own; in other words, it keeps the drawer together mechanically. Glue is added for extra strength.

Dovetail joint types

We’ll talk about four main types of dovetail joints: through, sliding, half-blind, and mitred. Dovetail construction is most often used for drawers, though you can find the style of joinery in a wide range of applications.

Through or English dovetail joint

The most basic type of dovetail joint is the through joint, also known as English style dovetail. In this woodworking joint, you can see the end grain of the boards whether you’re looking at the front or the side of the drawer. Sometimes, drawers will have veneers on the front to hide the joinery. That’s not always the case, as many woodworkers like to show dovetail joints as a point of craftsmanship.

Sliding or French dovetail joint

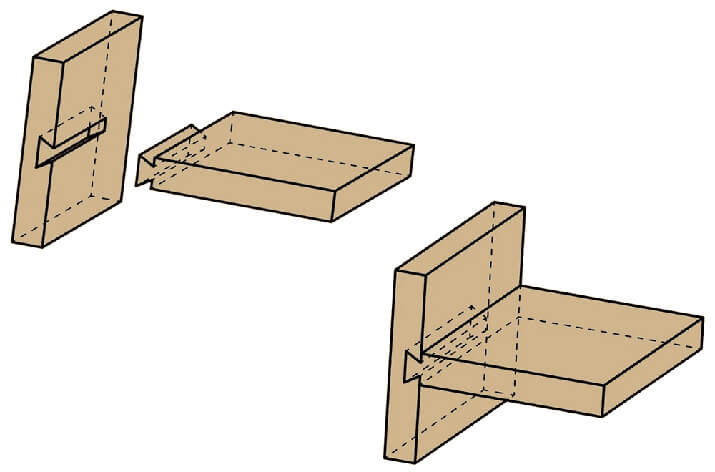

A sliding dovetail can be used at any point along a wood board, not just the end. This type of woodworking joinery is often used in curved drawers since it’s easier to position at an angle. In this dovetail joint, there is only one tail that slides in between two pins.

Half-blind dovetail joint

In this style of dovetail joinery, you can only see the pins and tails if you’re looking at the side of the drawer box. The joints are only routed halfway into the drawer front, so they are hidden from view from that angle. These joints are called half-blind dovetails since you can only see them from the side.

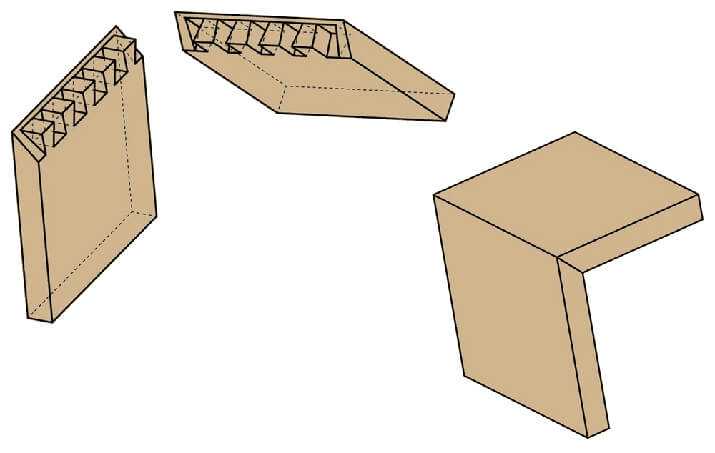

Secret mitred dovetail joint

In this type of dovetail joint, the joints are completely hidden. From looking at the drawer, you wouldn’t know that the drawer sides meet the front with dovetail woodworking joints. When done correctly, the grain of the wood will continue seamlessly across the front and sides of the drawer.

How Do You Make Dovetail Joints?

There are two main methods of making dovetail joints: use hand tools to carve the joints or use power tools. Some custom cabinet makers do cut dovetails by hand, but doing that is very labor-intensive. You’ll pay a premium for specialty handmade pieces.

The more economical way is to use a router and a dovetail jig to carve dovetails. The dovetail jig provides a form for special router bits to follow and create even dovetails. With a jig, you can line up both the drawer front and sideboard and rout both channels at the same time.

Benefits Of Dovetail Joints

If it isn’t obvious by now, one of the main benefits dovetail construction gives furniture is strength. While it looks elegant, it’s not all for show. If it were, people wouldn’t create secret mitred dovetails to hide them. In that case, the only reason for the dovetails is for added stability.

Dovetails are the strongest type of wood joint, in fact. They give a large surface area for wood glue, but you don’t need to use glue in small constructions. Dovetails are stronger than other types of joints like butt, lap, or rabbet joints, which are used by some big-box store cabinet makers.

At Kitchen Cabinet Kings, we only use dovetail joints for drawer boxes. Whether you go with RTA or pre-assembled cabinets, you’ll get quality that’s built to last.

![See your dream kitchen in 3D [GET YOUR FREE DESIGN]](https://cdn.kitchencabinetkings.com/blog/wp-content/uploads/see-your-dream-kitchen-in-3d.webp)

![Contractor Discount Program: Offering contractors and builders special volume discounts on all applicable orders [LEARN MORE]](https://cdn.kitchencabinetkings.com/blog/wp-content/uploads/contractor-discount-program.webp)

![Explore our photo gallery [GET INSPIRED]](https://cdn.kitchencabinetkings.com/blog/wp-content/uploads/explore-our-photo-gallery.webp)

![What everyone is saying about KCK [READ REVIEWS]](https://cdn.kitchencabinetkings.com/blog/wp-content/uploads/what-everyone-is-saying-about-kck.webp)

![Get a cabinet sample [SHOP SAMPLES]](https://cdn.kitchencabinetkings.com/blog/wp-content/uploads/get-a-cabinet-sample.webp)

![Pay over time, on your terms with Affirm [LEARN MORE]](https://cdn.kitchencabinetkings.com/blog/wp-content/uploads/pay-over-time-on-your-terms-with-affirm.webp)

Andrew, been shopping around. By the look of the install videos your cabinets look more solid than others. Thicker panels. Nice solid looking plywood. Curious about how the nails using a nail gun affects the finish. Wouldn’t you see irregular nail heads? Or do you only apply nails over surfaces that will not be visible in the end?

Screw covers inside the cabinet are recommended for mounting the back of the cabinet to the wall for the best finished look. To our knowledge, irregular nail heads wouldn’t be visible in the end. Please let me know if you have any other questions.